Working principle and configuration scheme of double-column hydraulic screen changer

Application scope of double-column hydraulic screen changer

Double-column hydraulic screen changer is more suitable for granulation, PE, PP, PPR, PERT pipes, plates, sheets, cast film, non-woven fabrics, chemical fiber spinning and other productions that require uninterrupted material flow during screen change and high continuity requirements.

Working principle of double-column hydraulic screen changer

It adopts double-column double-flow channel design, internal heating, fast heating, uniform temperature, and two filters work at the same time during normal production. When replacing the filter, one filter works and the other is replaced. The feed and exhaust device is designed. Through automatic or manual control of feed and exhaust, the screen can be changed without stopping, without leakage, without interruption of material flow, small fluctuation of material pressure, small impact on production, and good continuity. Suitable for production of various working conditions with continuity requirements.

Features of double-column hydraulic screen changer

1. Good sealing structure design, no leakage and no seepage under high temperature and high pressure conditions, effectively reducing the resistance of screen change and reducing the working pressure of the hydraulic system.

2. Large filtering area, suitable for extrusion production of different materials and different process properties.

3. Alternating working mode to ensure stable material flow and process repeatability during screen changing.

4. High precision machining quality, and the exhaust and material guide channel matched with it, embody the excellent effect of filtration + exhaust.

5. The product has been adjusted to nitriding treatment, and the service life has been greatly extended.

6. The overall design of the product is reasonable, easy to operate, and the effect is excellent.

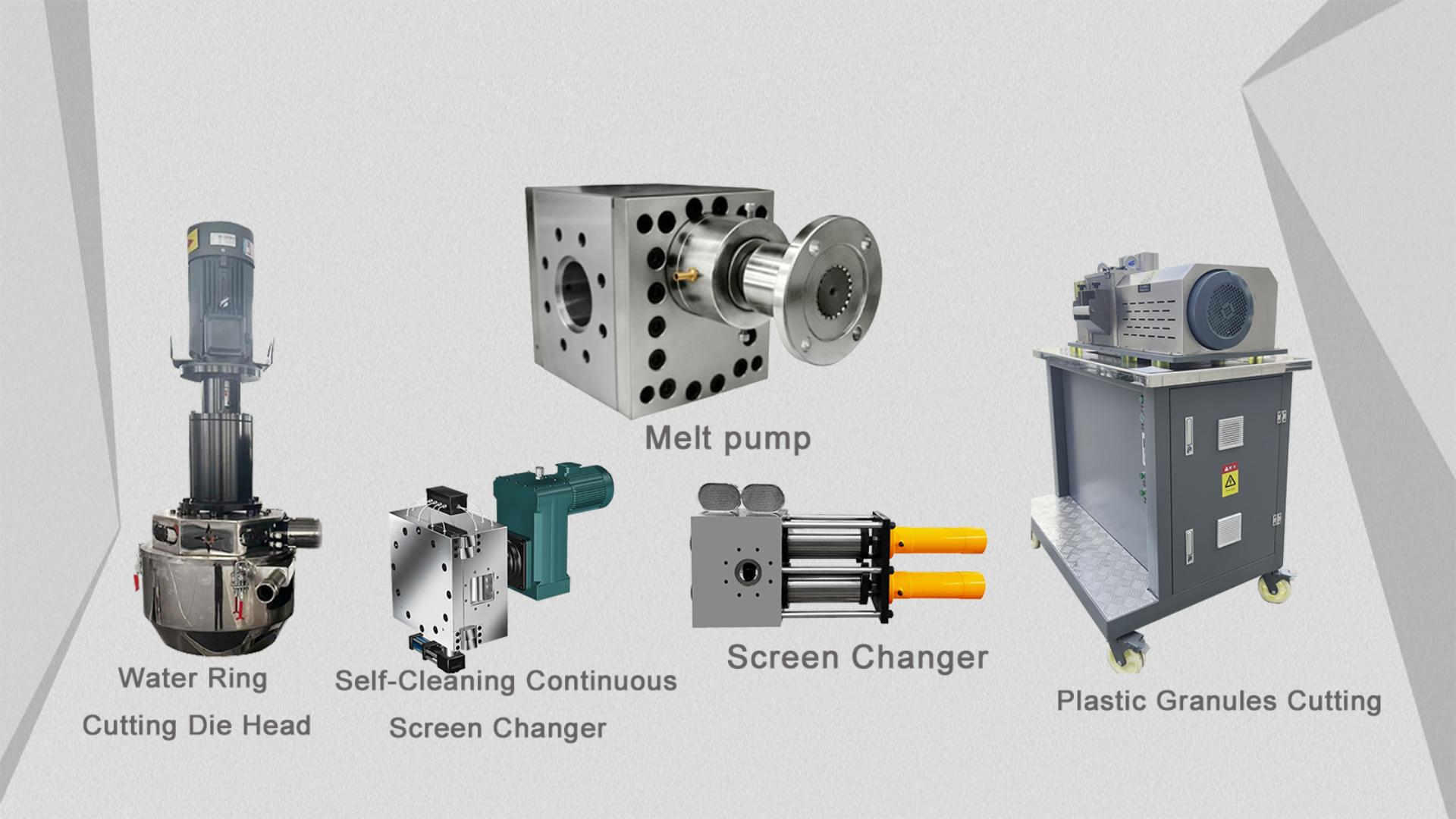

Double-column hydraulic screen changer configuration plan

1. Screen changer body + energy storage hydraulic pump station + heating device (standard configuration).

2. Screen changer body + energy storage hydraulic pump station + heating device + electrical control cabinet (customized configuration).