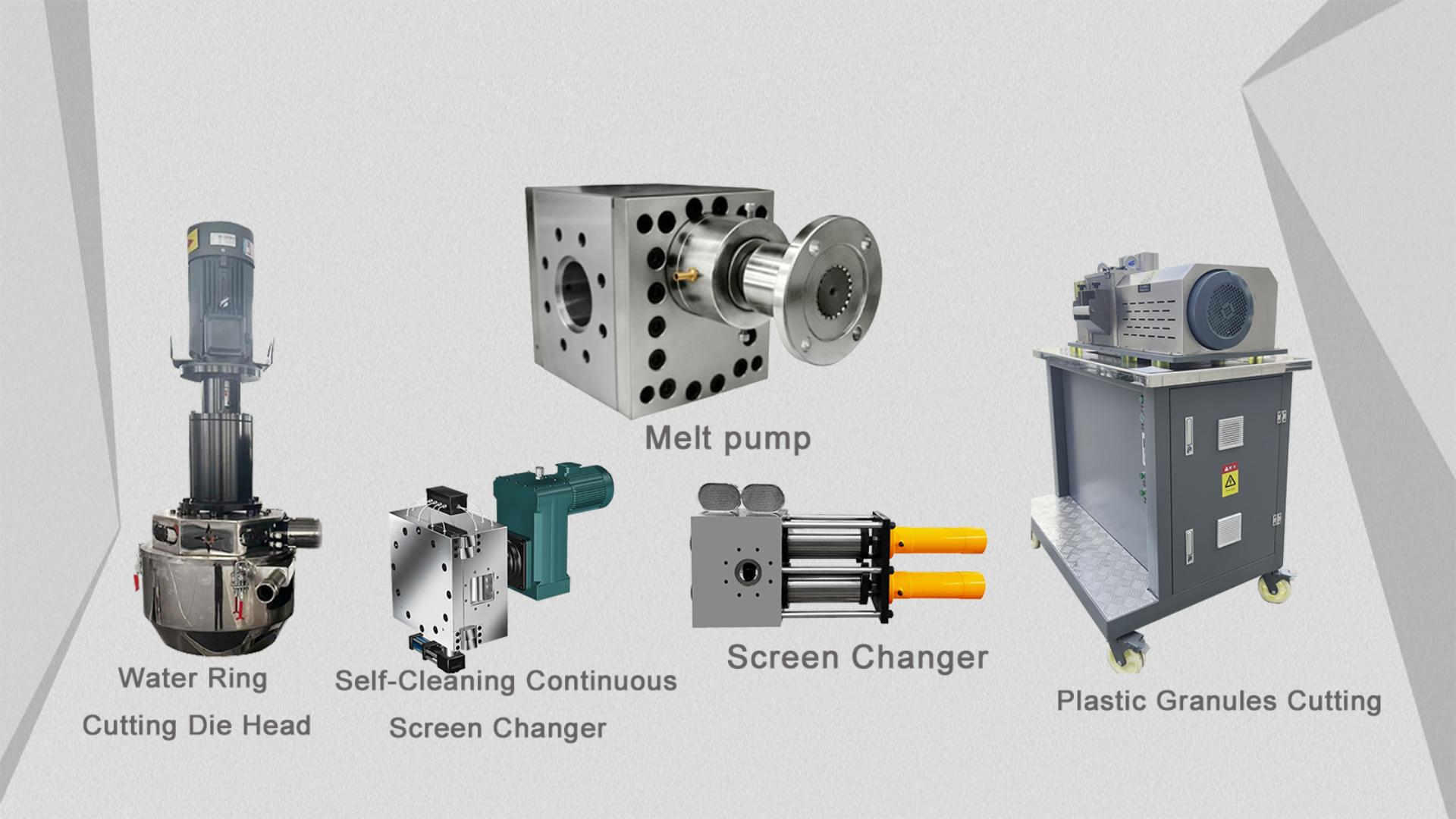

The integration of gear pumps and screen changers effectively ensures stable melt pressure during plastic pelletizing, achieving precise filtration and uniform pellet production.

Gear pumps provide reliable support for maintaining consistent melt pressure in plastic pelletizing processes, while screen changers remove impurities to deliver cleaner plastic pellets. In the screen changer module, two options are available:

1. Hydraulic Screen Changers (Traditional Type)

o These require manual replacement of screen plates.

o Subcategories include:

§ Plate-type: Suitable for low-pressure production lines.

§ Piston-type: Designed for high-pressure applications.

§ Belt-type: Features automatic belt movement driven by pressure, eliminating manual screen replacement.

2. Disk-type Filters (Advanced Type)

o No screen replacement is needed during production.

o Equipped with an automatic slag discharge system that periodically removes impurities, significantly reducing labor.

o Ideal for dirty material streams but currently limited to coarse filtration; fine filtration requires further development.

Selecting the appropriate filter configuration depends on your production line requirements. Additionally, whether to install a gear pump should be evaluated based on specific operational needs.

Contact: Asha Lee

Phone: +86-17796651219

Whatsapp: +86-17796651219

Add: Zhongyuan district Zhengzhou China