Extruder Screen Changer: Core Role in Foaming Production Lines

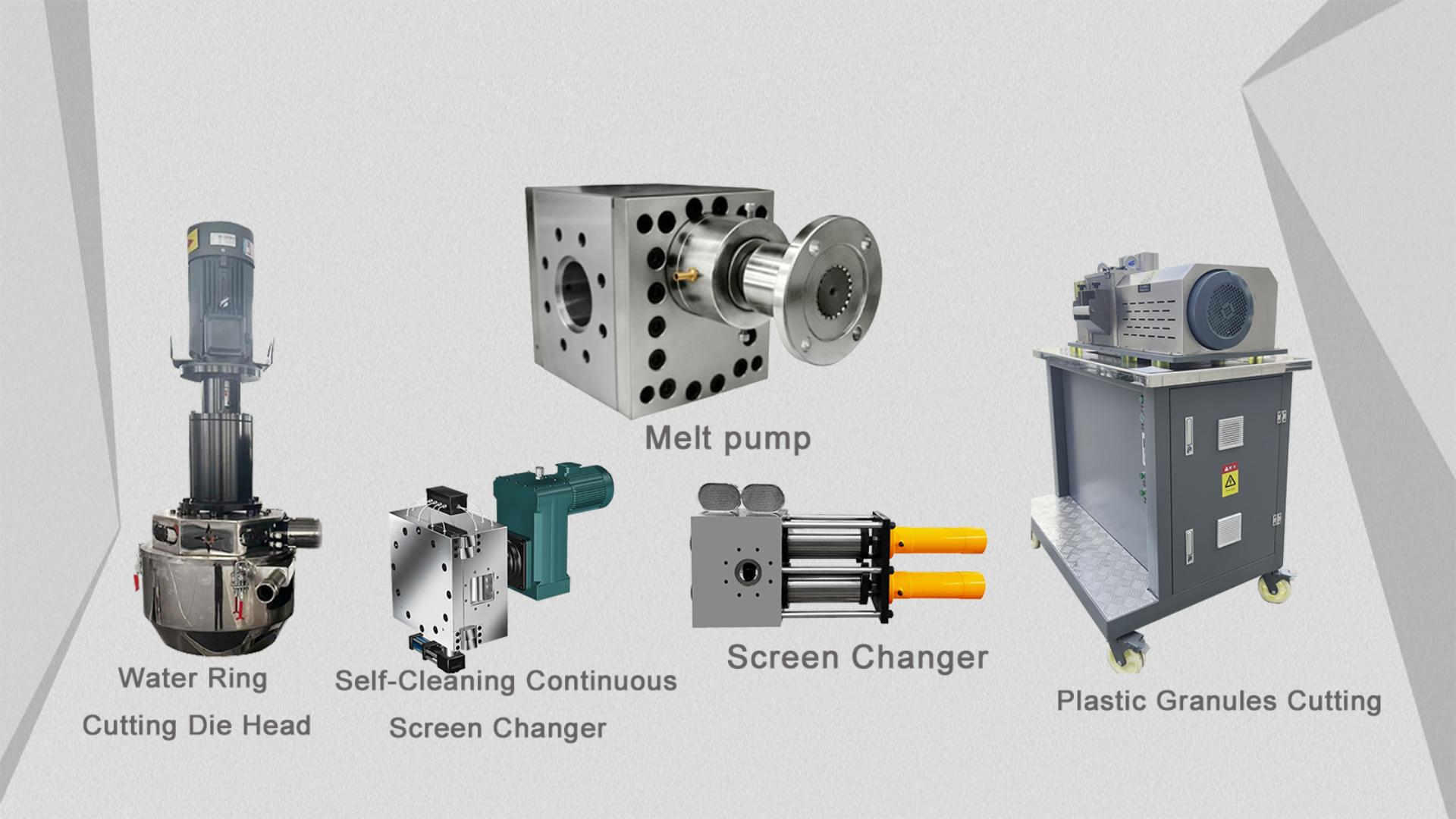

In plastic foaming production, the extruder

screen changer is an indispensable key device—installed between the screw extruder and the die, it directly impacts product quality, equipment lifespan, and production efficiency. Its core roles are as follows:

1. Filters Impurities, Guarantees Melt Purity

Raw plastic pellets (e.g., polyethylene) often contain impurities like unmelted particle clusters, dust, or foreign objects. If these enter the die, they will block nozzles, cause uneven foaming, and damage product performance. The screen changer filters impurities before the melt reaches the die, ensuring pure melt and laying the foundation for high-quality foamed products.

2. Enhances Plasticization & Homogenization

Adding a screen changer increases the die back pressure, which promotes full mixing and uniform plasticization of raw materials during extrusion. For foaming materials, uniform plasticization helps form consistent cell structures and smoother surfaces, significantly improving product texture, gloss, and buffer performance.

3. Removes Moisture & Volatiles

Moisture and volatiles in raw materials can form bubbles or voids in foamed products, reducing density and strength. The screen changer assists in expelling these substances during filtration, ensuring the melt’s stability and the foamed material’s structural uniformity.

4. Protects Dies, Lowers Costs

Dies are high-cost components in foaming lines. Impurities can cause severe wear to die surfaces, leading to frequent replacements and increased costs. By blocking impurities, the screen changer minimizes direct contact between impurities and the die, extending the die’s service life and cutting production costs.

As foaming technology advances, the screen changer’s role becomes more critical—it boosts product quality, reduces energy consumption, and supports the industry’s shift toward high-precision production.