Melt Pump: Solution for Thickness Variation

Thickness variation in thin products like films, profiles, tubes, and sheets leads to resource waste and raw material loss. The problem can be categorized into:

Pre-Die Problems

These relate to inconsistent polymer behavior due to:

•Irreproducible batch quality

•Unstable extrusion parameters: pressure, temperature, load, speed

Post-Die Problems

These are easier to identify and address, typically involving:

•Uncorrelated forces between output and attraction

•Issues with parallelism

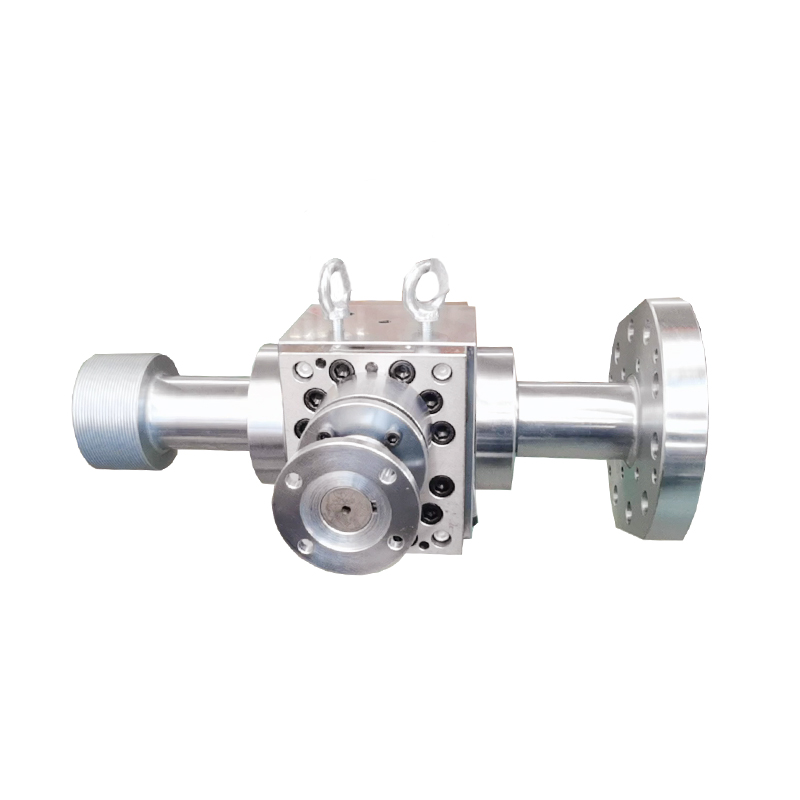

Solution: Gear

melt pump

A gear melt pump can neutralize pre-die issues, allowing separate management of post-die problems. This approach is more efficient and cost-effective.

Benefits of a Gear Melt Pump

•Pressure Transfer: Reduces screw-barrel torque, auto-heating, and energy consumption.

•Increased Production: Boosts flow and production.

•Pulsation Elimination: Stabilizes pressure and flow.

•Dimensional Accuracy: Improves accuracy and appearance.

•Reduced Scrap: Lowers scrap production.

•Improved Quality: Ensures better homogeneity and pellet size control.

•Temperature Control: Enhances temperature regulation.

•Production Flexibility: Shortens start-up times.

Using a gear melt pump improves product quality, efficiency, and cost savings.