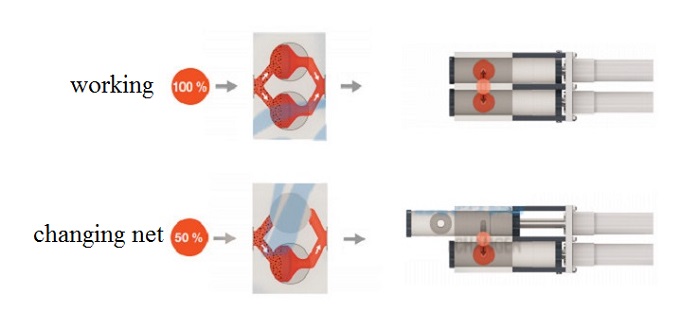

Because of long production process of plastic plate and sheet, when changing screen, if the production interruption will be very troublesome and wasteful. And in the view of this working condition, the stability requirement of changing net is high. The net changer equipment is composed of the main body of double piston screen changer, the skateboard, the high temperature oil cylinder, the heater and so on. The sealing parts are made of special alloy steel, which is specially processed by many processes, such as quenching and tempering, nitrding, fine grinding, etc., and adopts special flow channel design and stabilizing structure. So this changer equipment can realize no stop, no leakage, and no interrupt production, less waste, save time and labor and cost.

The state of

production time

The main cavity

of the heated screen changer is composed of two filter plungers, each with a

filter chamber. The melt flow is divided into two strands into the filter chamber

and is guided into each of the two filter chambers.

Changing net

When it is

necessary to change the screen to reach the set pressure, a plunger will be moved out of the main cavity, so that the filter room will reach the position

of changing screen/net, then the dirty screen will be removed and replaced with

a new one. During the screen change, the filter cavity of the other piston is

kept in the production position and the melt flow will be not interrupted. And

now 50% of the filtration area can still be used for filtering. Due to the use

of special exhaust procedures, after changing the net, the air will not enter

the technological process.

Contact: Asha Lee

Phone: +86-17796651219

Whatsapp: +86-17796651219

Add: Zhongyuan district Zhengzhou China