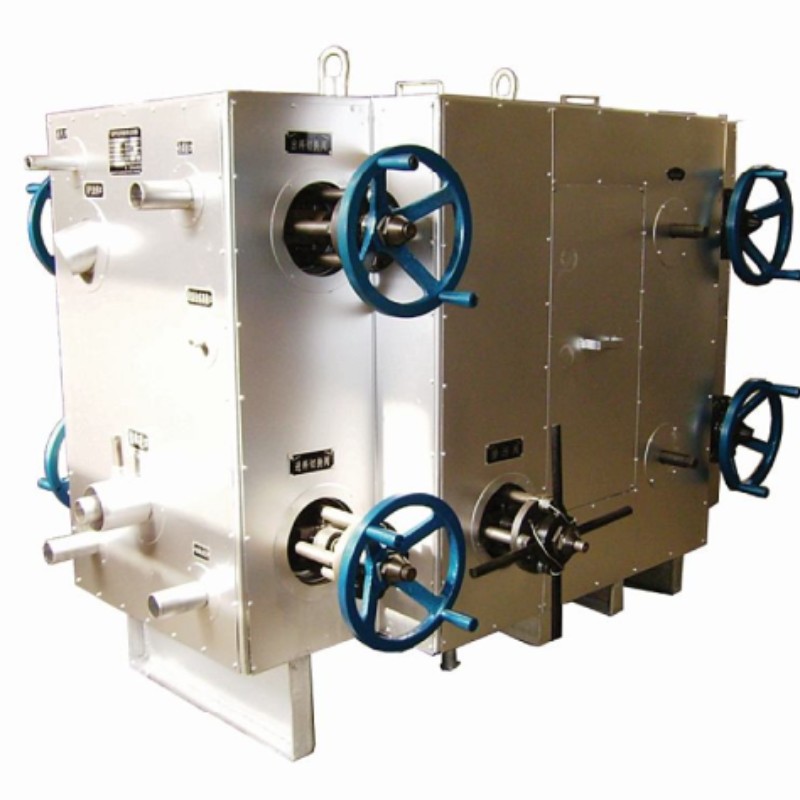

Vertical self-sealing series

melt filter for spinning polyester staple fiber

Applicable production line: Chemical fiber spinning, nonwoven fabric production, recycled polymer pelletizing, stretch film production, and plant fiber processing.

Applicable material: Polyester filament (POY, FDY), nylon (PA6, PA66, PA11) filament, both long and short fibers, nylon-polyester composite yarn, polypropylene spunbonded nonwoven fabric, polypropylene (PP) long and short fibers, polyethylene (PE) spinning, BOPET stretch film, spandex spinning, viscose fibers, plant fibers, and other related fields.

Filtration method filtrating candle mesh

Filtration area(m²) 2.5,3.5 4.5, 5.5, 6.5, 7.5, 9.5, 12, 15

Maximum working pressure 16MPa

Filtration accuracy 60 mesh - 400 mesh

Heating power 5Kw--45Kw

Heating media heat transfer oil, static toluene

Characteristic:

1. Filter chamber: Advanced self-sealing device is adopted, making operation labor-saving, convenient, and safe, thus extending the service life of the main machine.

2. Inlet and outlet valves: Utilizing a well-designed, advanced two-joint separation, metal soft and hard sealing, and quick, smooth three-way switching valve with no dead corners.

3. Exhaust valve: Employing a single-cylinder straight discharge, side drainage, ensuring quick, smooth, safe, and efficient operation.

4. Drain valve: Equipped with a large-diameter vertical drain outlet for rapid drainage, featuring a horizontal control handwheel for convenient operation.

5. The large filtration area, extended filtration cycle, excellent filtration performance, and professional component configuration prolong the replacement cycle of spinning components, reduce direct production costs, and indirectly decrease energy consumption expenses.